Products

Ablative

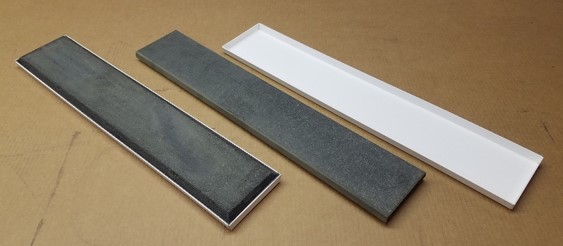

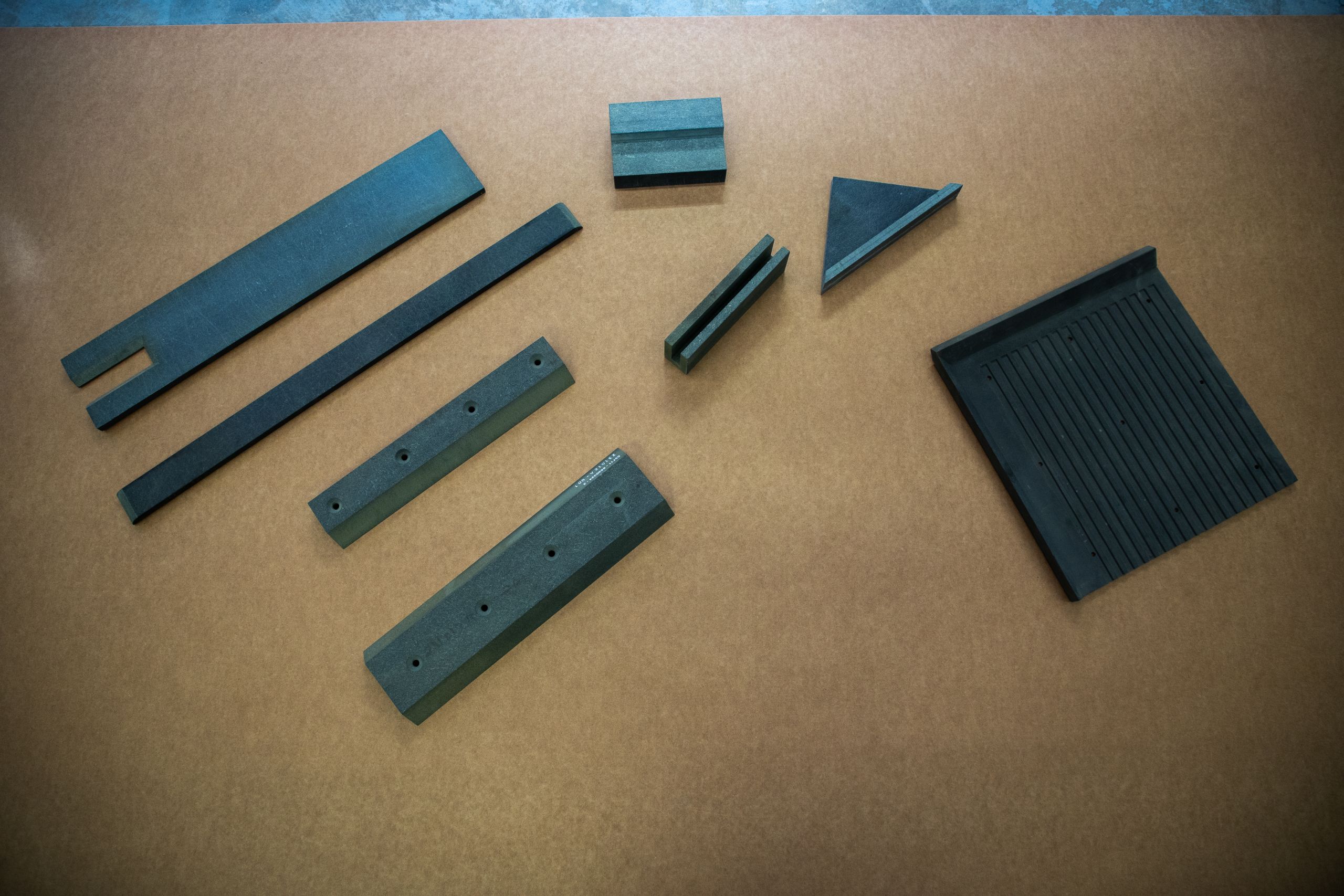

SMC manufactures a variety of Ablative materials used for exhaust mitigation on US Navy launcher systems. Primary materials are certified to Naval Weapons Specifications WS 19133 & WS 19134. SMC is a qualified manufacturer of these materials per WS 20165 & WS 20166.

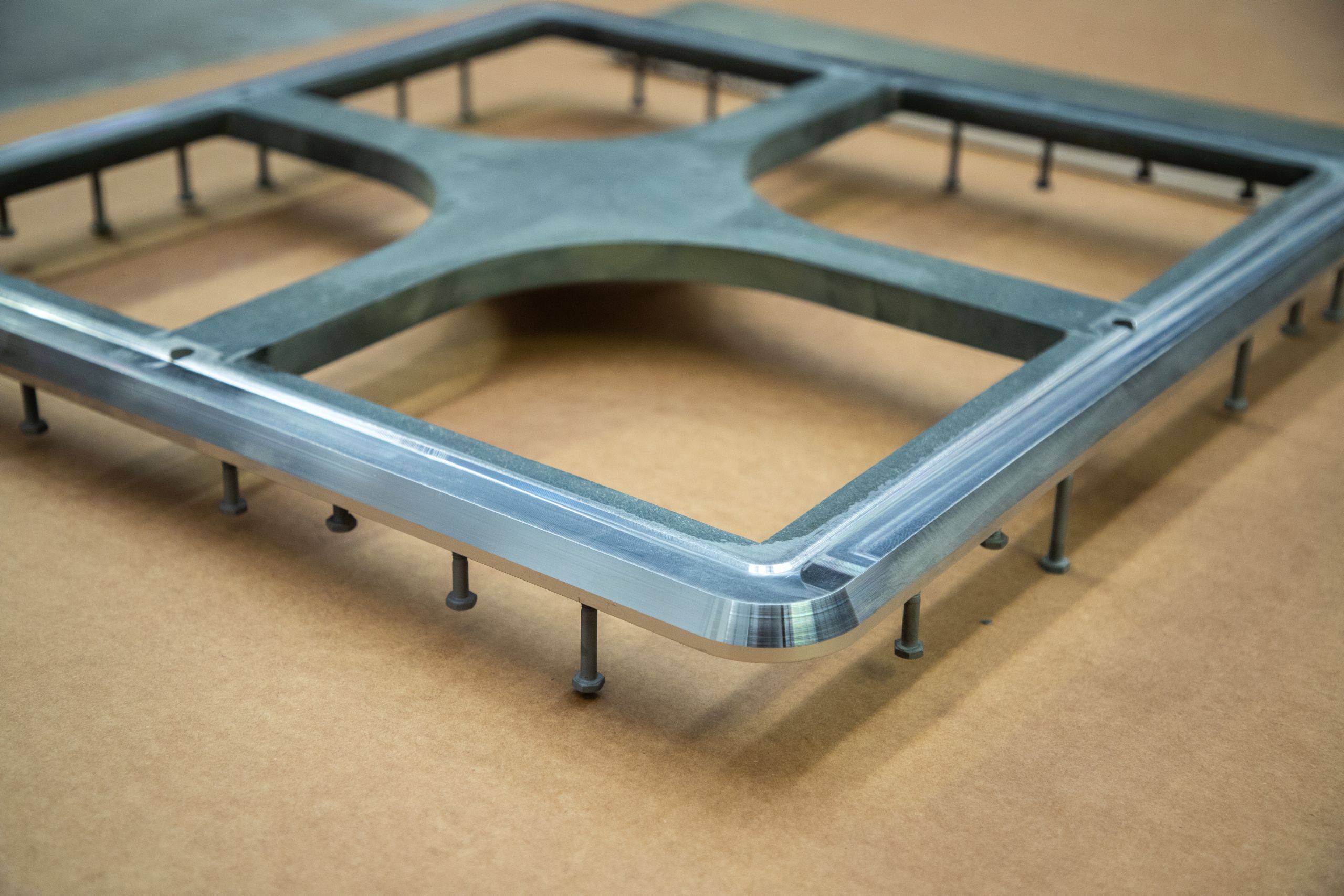

SMC also abrades, cuts, machines, cleans, bonds & finishes these ablative materials into parts and assemblies varying in size up to 5 ft X 10 ft and any thickness up to 4 in.

Composite Laminates

SMC is capable of molding a variety of composite materials using vacuum, VARTM, compression and autoclave molding. Core competencies are in Aramid and Fiberglass Spall Armor per the following Military Specifications:

• MIL-DTL-62474 LAMINATE: ARAMID – FABRIC REINFORCED, PLASTIC

• MIL-DTL-64154 LAMINATE: FIBERGLASS – FABRIC REINFORCED, PHENOLIC

Bonded / Finished Assemblies

All products can be cut, machined, bonded, hardware attached and painted per specification. Following is a list of current specifications SMC works to:

- MIL-DTL-53072 – Chemical Agent Resistant Coating (CARC) Application Procedure.

- TACOM 12577737 – CARC Coating System

- TACOM 12350824 – Paint System, CARC

- NSSC WS19166 – Abrasive Cleaning of Materials

- NSSC WS19201 – Application of Epoxy Polyamide Paint

- NSSC WS20174 – Bonding with Structural Epoxy Adhesive