Capabilities

Weaving / Coating

SMC maintains Dornier looms and associated equipment for weaving Aramid fabrics. Fabric produced in-house is generally for internal consumption and low quantity orders. SMC also has the capability to scour, water repellant treat and coat aramid fabric with PVB/Phenolic resin.

- Benniger Sectional Warper, 200 end creel

- Five Dornier Looms

- Vald Henrikson Scouring Jig

- Marshall & Williams Horizontal Treater

- Menzel Roto Gravure Coater

Prepreg Cutting

SMC has the equipment to economically cut prepregs either into flat panel configurations or shaped patterns.

- Two Lectra Vector 2500 Vertical Knife Cutter

- Two Slitter Sheeter, 85” Width

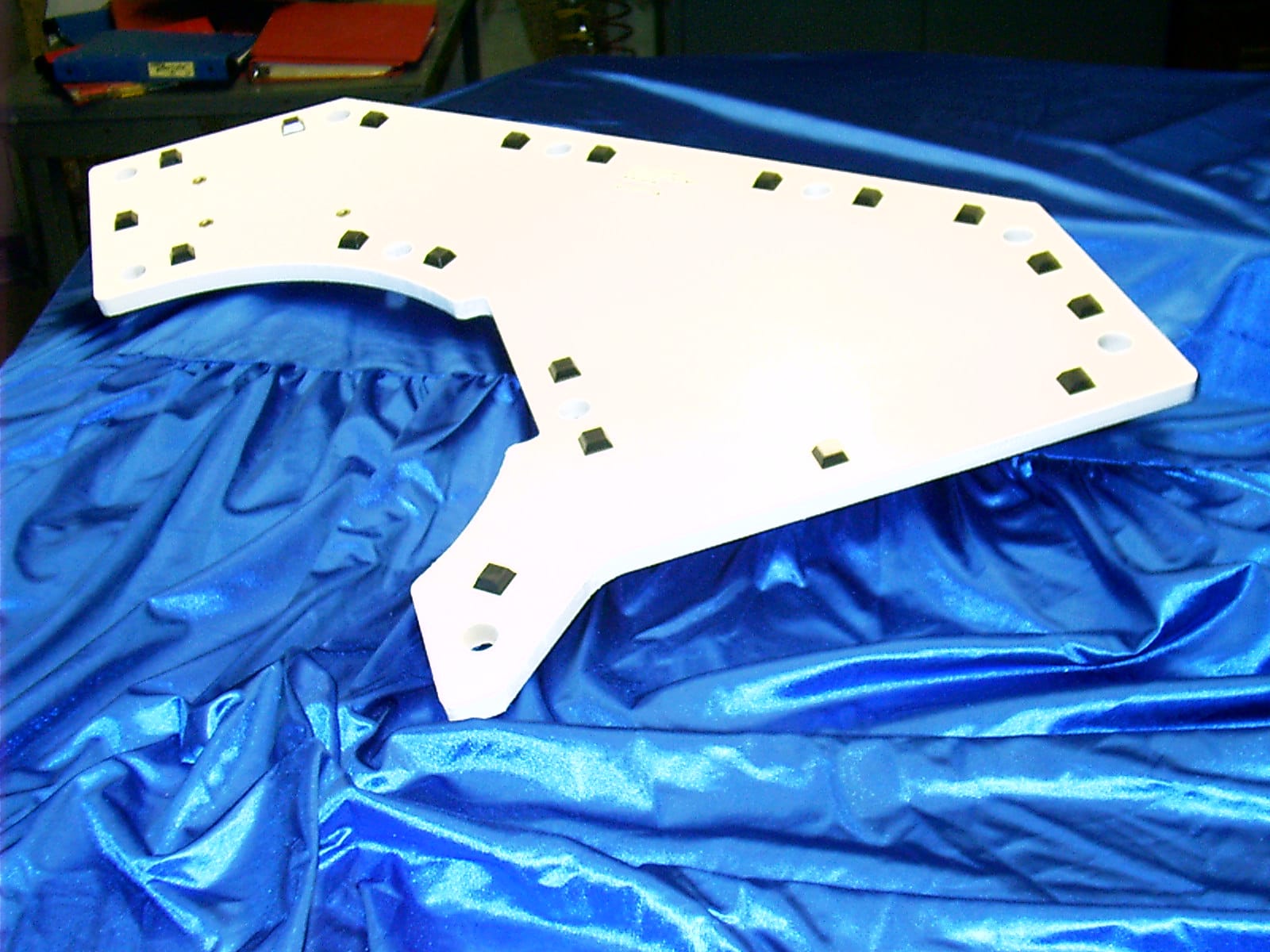

Molding

SMC can mold either flat panels or contoured shapes up to 60” x 120” x 4” thick.

- Compression Molding – Hydraulic Presses capable of 200 to 1,500 ton

- Autoclave Molding capable of reaching 175 psi and temperature up to 500 degrees Fahrenheit.

- Three Ovens capable of 500 degrees Fahrenheit, two with vacuum ports

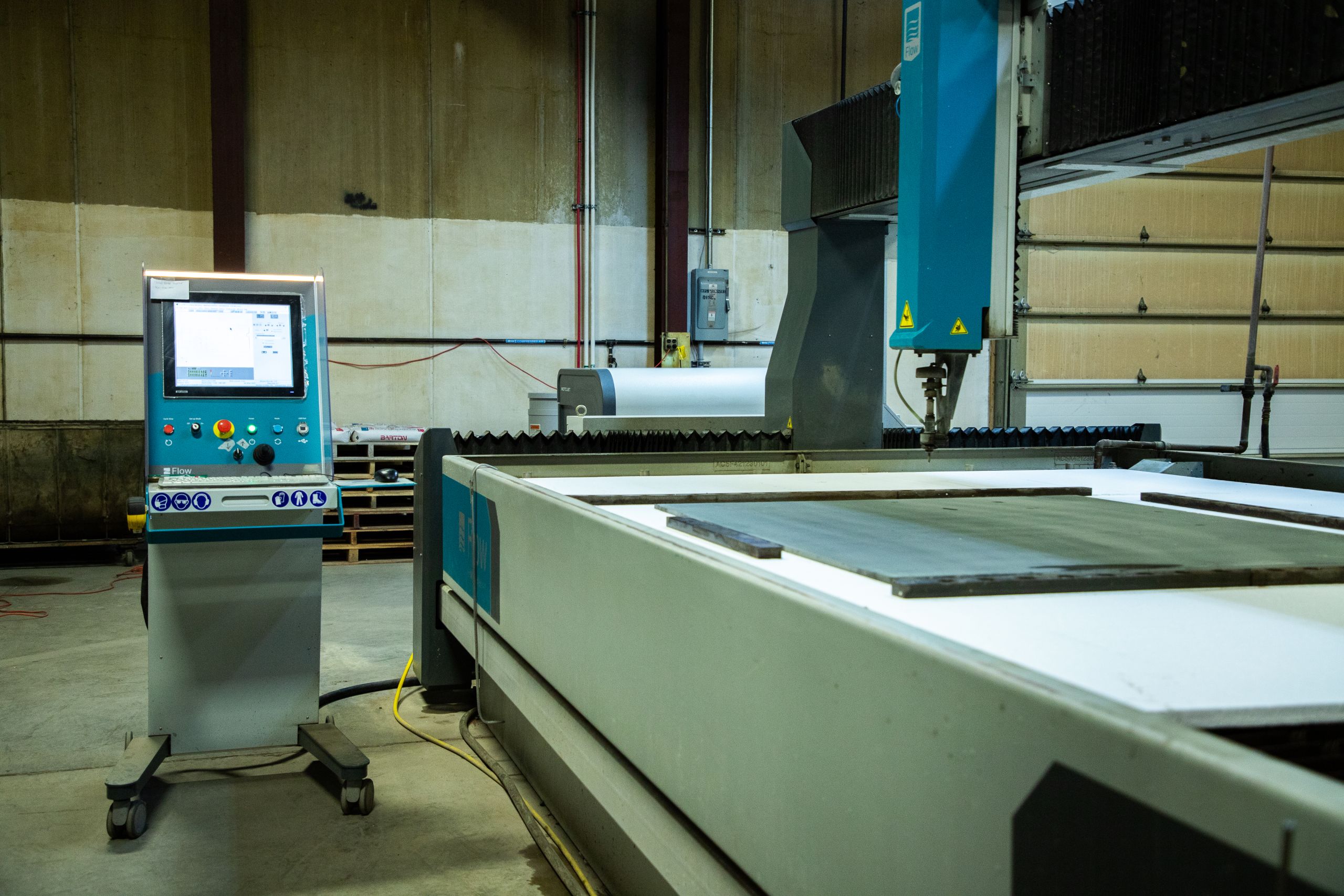

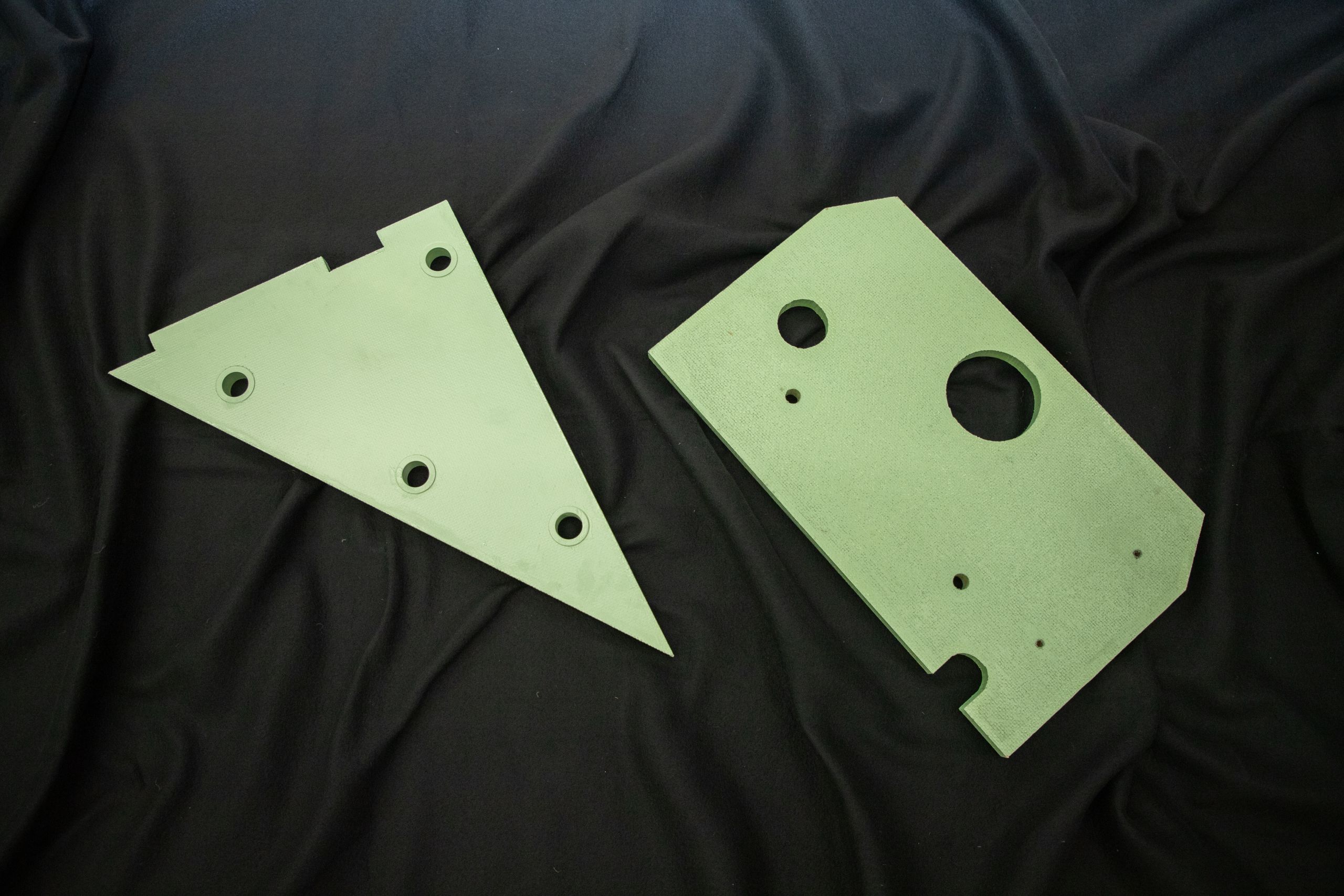

CNC Machining

SMC operates CNC cutting equipment to transform molded pieces into finished parts of nearly any configuration.

- Four CNC abrasive waterjet cutting centers

- Five CNC machining centers, 3-axis

Part Finishing

SMC will complete the part(s) with any needed bonding, hardware installation, priming/painting and final assembly.

- Two paint and finish booths

- Abrasive Grit Blast booth

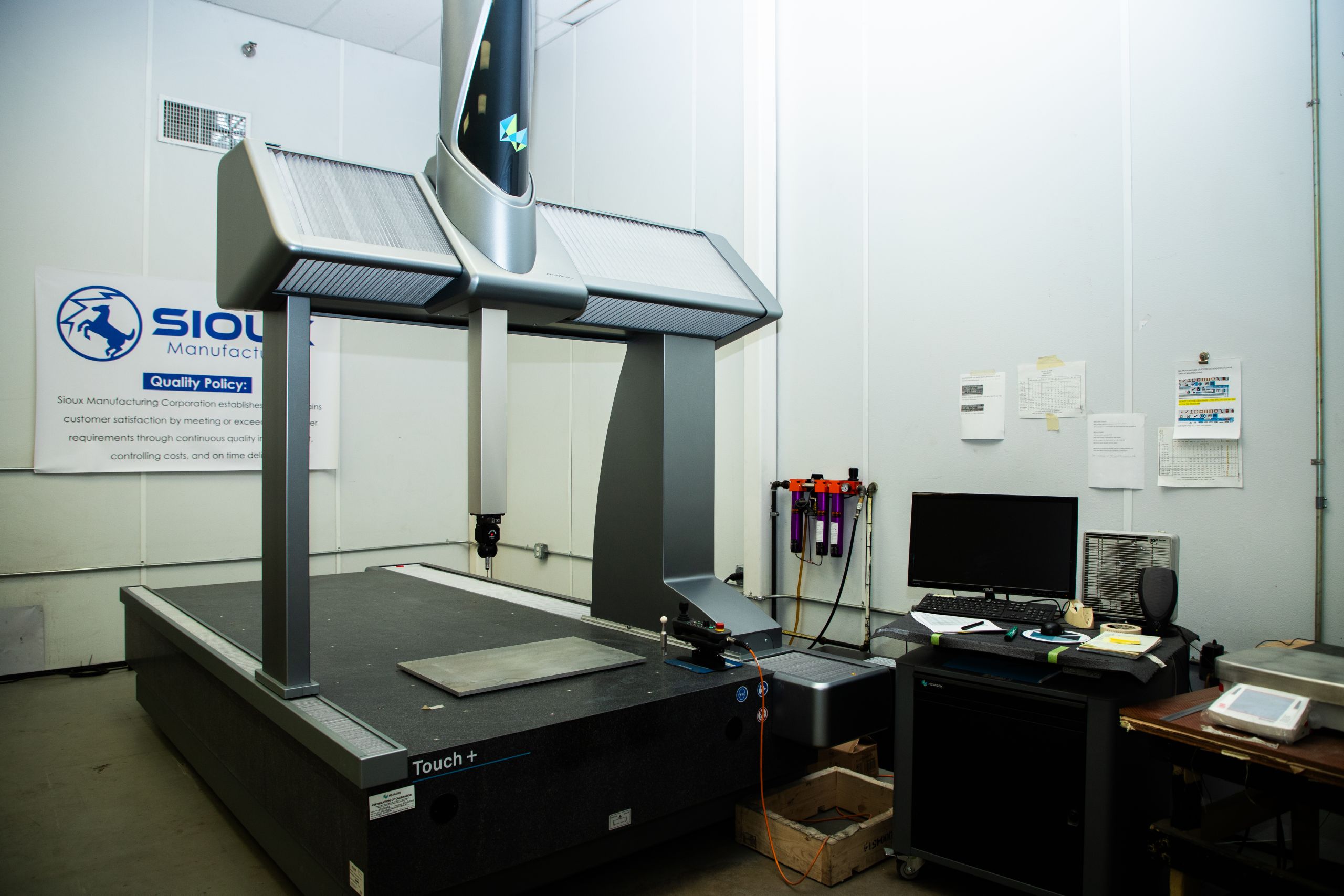

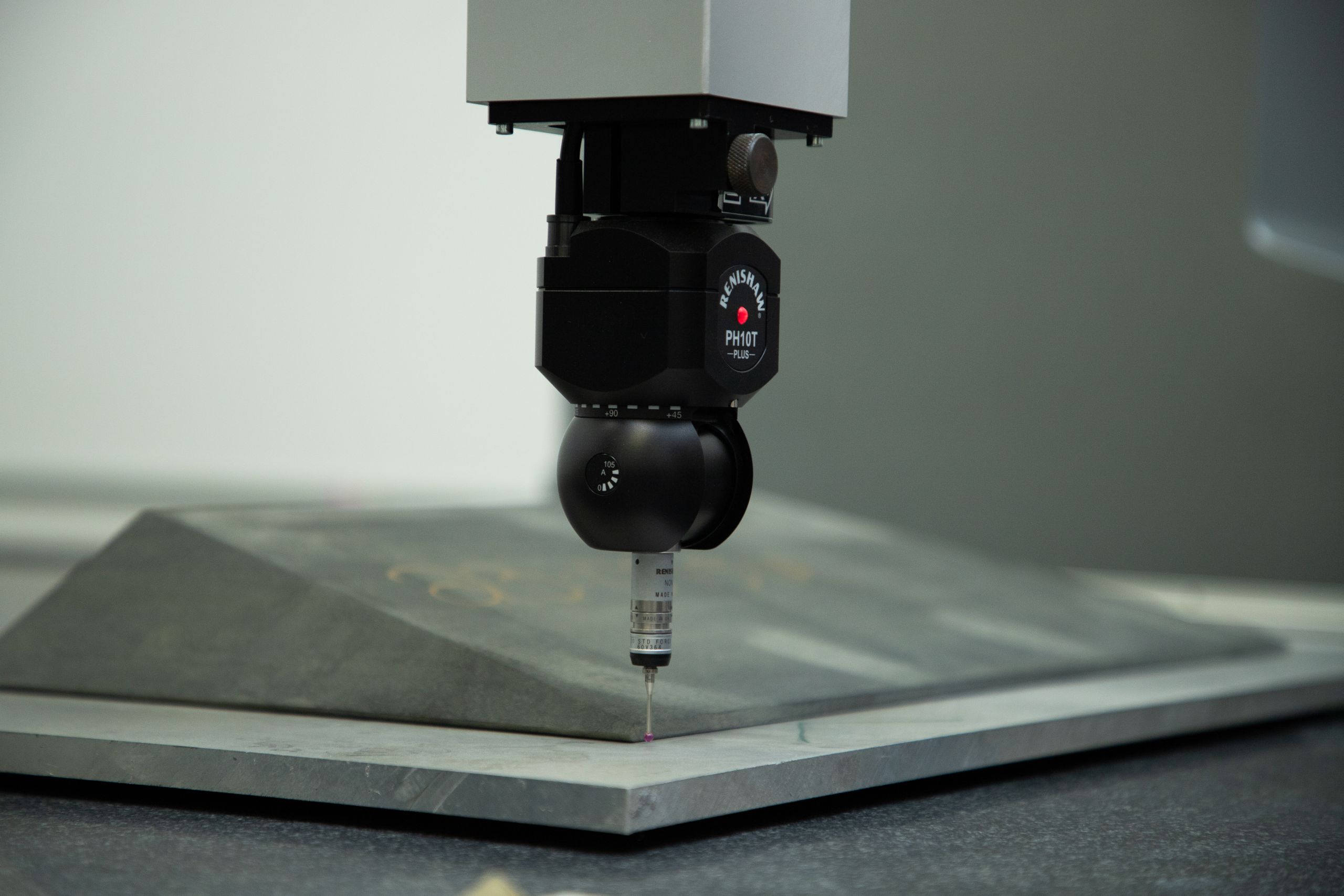

QA Testing

SMC maintains all the procedures & test equipment to perform receiving, in-process and final inspection to ensure all materials, processes and parts meet customer requirements.

- Instron – Model 34TM-50 Dual Column Mechanical Test System.

- Hexagon Global S 12.22.10 CMM (1200 mm x 2200 mm x 1000 mm)

- FaroArm® 3D Measuring Arm

- Ballistics Range